Blog

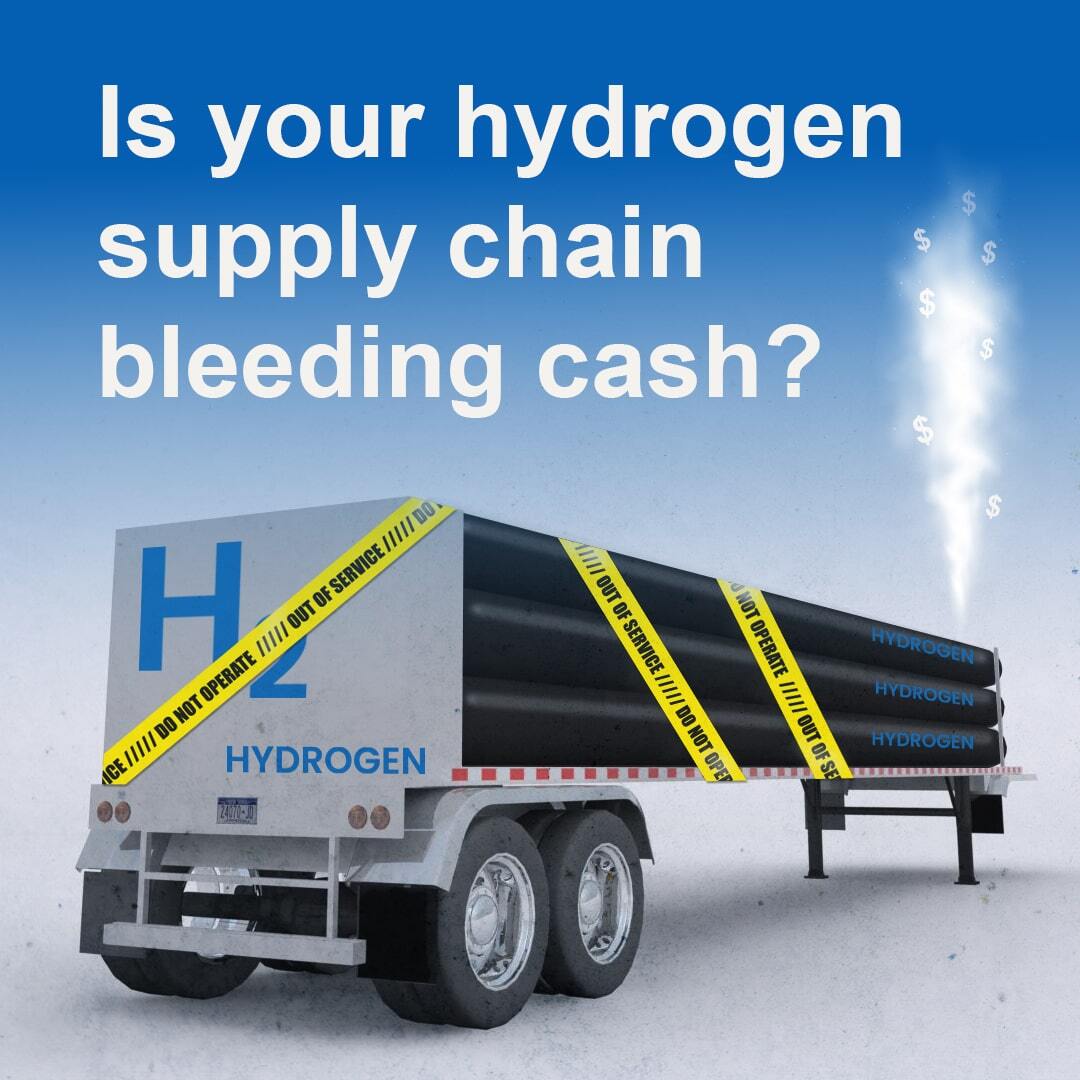

The ripple effect of a single hydrogen leak can be catastrophic.

Imagine grounded trailers, towns left without vital fuel, and the astronomical costs of troubleshooting, emptying, and refilling cylinders for testing. We’ve heard the stories – months of halted operations, millions lost, and irreparable damage to brand reputation. These aren't just 'problems'; they're threats to your business continuity and profitability.

At Oasis Engineering, we understand these challenges intimately. That’s why, in collaboration with industry partners, we developed the TH400 series cylinder valves. Engineered for high working pressures (up to 520 bar), these aren't just valves; they're a solution to the pains that plague hydrogen transport. The TH400’s standout feature is its commissioning port, specifically designed to isolate individual cylinders for testing.

This innovation eliminates the need to dump and refill entire trailer loads of fuel, saving you precious time and thousands in wasted product. Furthermore, our intuitive quarter-turn lever handles provide instant visual confirmation of valve status, preventing costly errors like unnoticed closed valves that can lead to unexpected fuel shortages on critical voyages. Discover how the TH400 series can transform your hydrogen operations, protecting your assets, reputation, and bottom line."